|

Any surface for whatsoever process - printing, glueing, coating, etc. - you want to use, has to be clean. Major inconvenient of wet cleaning process is impossibility of precise control of cleanness of active agent from one cleaning process to another. More one uses the agent more residues from previously cleaned surfaces stay on surface newly cleaned. | |

| Only one method, which allows to avoid such problem is plasma cleaning and it is because the plasma is constantly renewable and the wastes of cleaning are continuously evacuated.

Nevertheless, plasma process is really advantageous only for final cleaning, when one has to have regular and required level of cleanness from piece to piece, from batch to batch, from day to day. |

|

|

|

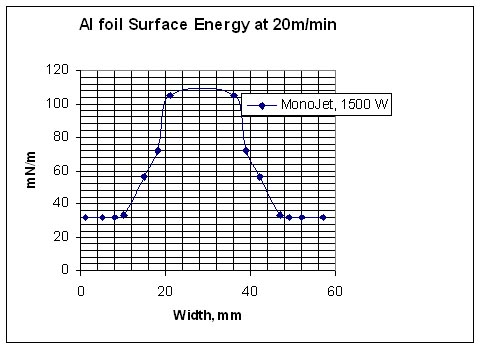

The best result would be a usage of convenient cleaning process to remove main quantity of impurities and than plasma cleaning to make sure that result is regular. The Advanced Machines' atmospheric pressure technology proved to be very efficient even when the surface to be cleaned is flowing through the dense and powerful plasma at a very high - up to hundreds of m/min - speeds. |

|

|

Flexibility of our atmospheric pressure plasma equipment and process, level of power and flexibility available make it possible to clean up the surface of stainless steel and aluminium bands and profiles directly at the exit of laminating machines. Absence of impurities even at the microscopic level insures the quality of your glueing, coating or printing processes. |

|